The Greatest Guide To Gable Spandrel Panel

Table of ContentsOur Insulated Spandrel Panel PDFsExcitement About Replacement Double Glazing Panels CostReplacement Glazing Panels Fundamentals ExplainedThe Facts About Gable Spandrel Panel UncoveredInsulated Metal Spandrel Panels - The FactsA Biased View of Aluminum Spandrel

Occasionally, there are worries connecting to having way too much unchecked daylight, occasionally referred to as glare. The challenge is to make every effort for the highest possible visible light passage (VT) and also the least expensive solar warm gain coefficient (SHGC) while not protecting against the glass from being as well reflective when watched from both the exterior as well as the inside, while managing glare.The units need to be completely set up in a factory and shipped to the website for setup on the building. The devices are positioned on the floors, bundled in cages, using the tower crane and reduced into location using a smaller sized crane or hoist had by the glazing contractor. The mullion measurements often tend to be slightly bigger than a stick system as a result of their open area as compared to television shape of a standard stick curtain wall section.

Devices can be set up in a manufacturing facility while the architectural frame of the building is being built. Where stick systems require numerous steps to set up and also secure the wall surface, unitized wall surfaces show up on the website completely put together allowing the floors to be shut in quicker (replacement double glazing panels prices). Unitized systems likewise need much less space on site for format thus offering a benefit for urban websites with area limitations.

The Basic Principles Of Gable Spandrel Panel

The interlacing upright mullions will commonly have 2 interlocking legs. One leg will certainly remain in the aircraft just behind the glazing pocket and also the other at the indoor face of the mullions. The interlocking leg in the plane of the glazing pocket will be secured by gaskets as well as is the primary line of defense against water as well as air seepage.

Systems whose attaching legs lock additionally endanger the capability of the system to accommodate motion. Some unitized designs are sensitive to small irregularities in the spacing of adjacent components; for instance, if the module joints are somewhat out of tolerance, gaskets may not be effectively compressed as well as dampness security might suffer.

The four-way junction refers to the area where four surrounding systems fulfill. This is where area labor should seal in between nearby units to attain a weather limited wall surface. The interlacing legs of the horizontal mullions are one of the most essential interface of a unitized system. Water that infiltrates the interlocking vertical mullions drains pipes to the interlocking horizontals that should gather and also divert this water to the exterior.

Little Known Questions About Gable Spandrel Panel.

These upstanding legs have gaskets that seal against the wall surfaces of the lower straight. More durable systems will certainly offer two upstanding legs with gaskets on both legs.

The pile joint is the horizontal joint where units from adjoining floors satisfy. Putting the stack joint at the sill of the vision glass (generally 30" above the floor) will certainly decrease the dimension of the upright mullions. This positioning uses the back period of the mullion above the anchoring factor at the slab to combat the deflection of the mullion listed below the slab (gable spandrel panel).

Define that research laboratory examinations are to be performed at an AAMA Accredited Laboratory facility. Field Mock-up: For all drape walls, stock or custom, require building and construction as well as testing of an area mock-up rep of the wall/window setting up. This is best scheduled prior to the release of shop drawings for window manufacturing, so that there is a possibility to make layout changes based upon the examination performance of the field mock-up.

About Replacement Double Glazed Glass Panels

The details connected with this section of the BEDG on the WBDG were created by board as well as are meant entirely as a way to highlight basic layout and construction ideas only. Ideal use as well as application of the ideas highlighted in these details will certainly differ based on efficiency factors to consider and also environmental conditions one-of-a-kind per task and also, as a result, do not stand for the final viewpoint or referral of the writer of each area or the committee members liable for the growth of the WBDG.

Continuous steel sill flashing at the base of the drape wall surface shields the wall surface framing below from leakage via the drape wall surface. glass glazing estimator Sill blinking ought to have upturned end dams and also fully sealed corners. Intermediate horizontal ought to be cried to the exterior as well as avoid water from draining onto the head of the glazing device below.

The Of Aluminum Spandrel Panel

Gasket height ought to correspond to the drape wall design stress. Stress matched rainscreen gaskets form a key climate seal at the face of the unitized upright stack joint why not try here in line with the horizontal rainscreen gasket at the system sill below.

Spandrel glass adapters are made use of to minimize the deepness of the glazing pocket to fit decreased profile of spandrel glass. Spandrel glass adapters must be completely bedded in sealer and incorporated with glazing pocket corner seals to prevent water leakage from polishing pocket to building interior. System dimension of mating head and sill squeezed out profiles enables specified flooring to floor deflection at the stack joint.

Intermediate horizontals quit at the face of the upright device jamb participants at each end. Devices are hung from the top or face of the adjacent floor or building structure using mated brackets and also field used screws with a minimum of clearance for gain access to and assembly. All connections and also braces located within the systems insulated or key weather condition seal areas are sealed with ideal sealer products during field setup.

Insulated Metal Spandrel Panels Can Be Fun For Anyone

non-heat-treated) or completely toughened up glass to remain in position till it can be changed. Whether heat-strengthened or fully solidified, heat-treated glass items are produced in a similar style and also using the very same handling tools. The glass is warmed to roughly 650 C (1200 F), then force-cooled to create surface area and edge click this site compression.

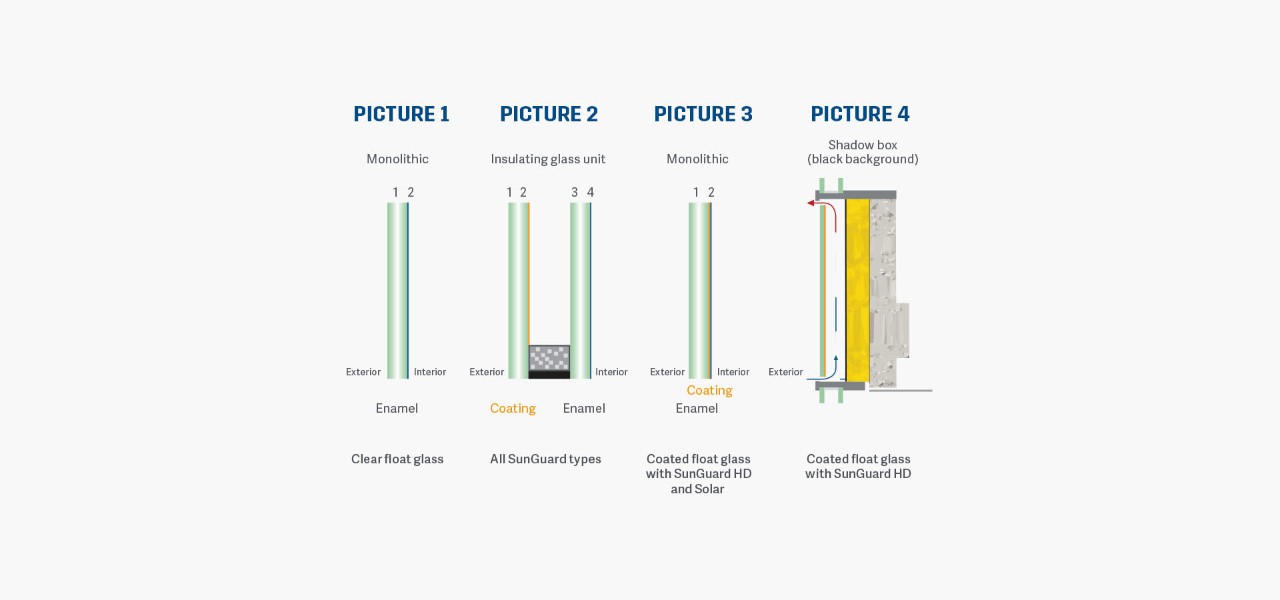

As indicated in Figure 1, insulation is usually utilized combined with spandrel glass. When the insulation is to be used directly to the opacified surface of the spandrel glass, it is necessary to collaborate with a glass spandrel maker, in addition to the glue and insulation providers, to make certain these items work with the opacifying material. gable spandrel panel.